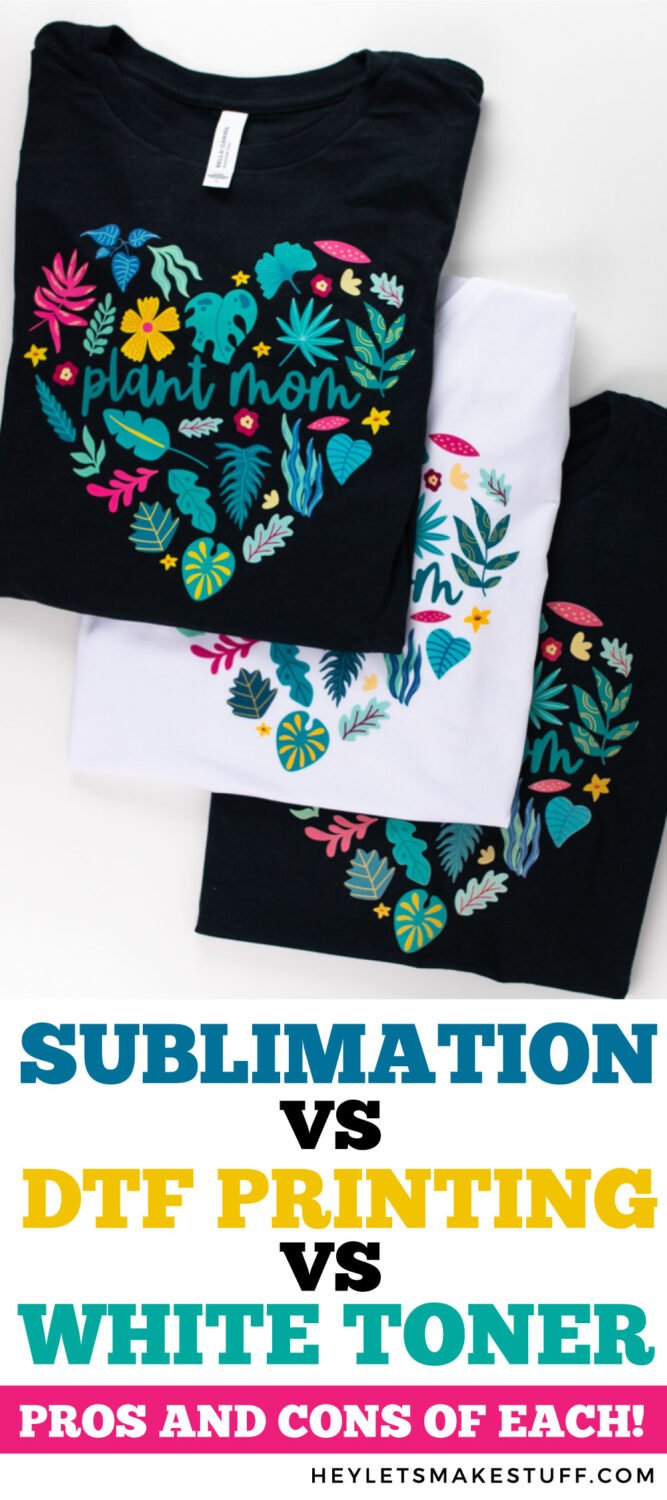

There are so many ways to apply an image to a garment! Here’s everything you need to know about the difference between HTV, sublimation, DTF, and white toner printing for all of your t-shirt decorating.

If there’s one thing I can tell you how to do on my channels, it’s how to decorate a t-shirt. T-shirt decoration has gone from the realm of handcrafting using tie-dye and puff paint to a huge world filled with technology. And much of that technology is becoming easier and easier for the everyday crafter to access.

But each type of technology has its advantages and disadvantages. And it’s important to know what you can do—and what you can’t do—with each type of t-shirt decorating method.

So in today’s post, we’re going to be comparing four different types of decorating methods: HTV (heat-transfer vinyl), sublimation printing, DTF (direct to film) printing, and white toner printing. These are all topics I’ve covered here on my blog and on my YouTube channel, but I’ve never done a big direct comparison of all four. I’ve linked to a lot of other tutorials through this post, if you’d like more information.

Watch the Video

Want to get a video overview all of these processes? Just hit play below! Or keep reading for a written overview.

Get the Free File

Want access to this free file? Join my FREE craft library! All you need is the password to get in, which you can get by filling out the form below. The file number is: S37.

The Best T-Shirts for Decorating

You all know that I am a HUGE fan of BELLA+CANVAS tees, so that’s what I’m using in my examples for t-shirt decorating in this post. I love that their tees are so soft and come in a wide range of colors and styles. I also love that they have eco-friendly business practices that make me feel confident in using their garments. They are the preferred tee of many small businesses as well as customers!

Check out their new HEAVY line, which features heavy-weight tees. These tees have a more boxy shape which is super trendy right now!

Did you know you can buy BELLA+CANVAS garments at wholesale pricing without a reseller license? Get a BELLA+CANVAS Maker’s Account! This account allows you access to the wholesale side of their business without the need for any permits or licenses. Even better? It’s free! Learn more in my post Buying Wholesale Blanks without a Resale License!

For sublimation, I am using a 100% polyester tee from another brand. This is because BELLA+CANVAS tees are primarily cotton so they don’t sublimate well. I did try sublimating their EcoMax tee, which worked pretty well, but I wanted to show what 100% polyester can do when it comes to color and vibrancy.

Heat Transfer Vinyl (HTV)

Heat transfer vinyl is a heat-activated transfer product that is cut on a cutting machine (like a Cricut or Silhouette) and then applied to a garment or other soft textile using a heat press. You may also hear this referred to as iron-on vinyl. It usually comes on a roll or in sheets. The most popular type of HTV is solid colors, but there are specialty HTVs, including patterned, holographic, glitter, etc.

HTV Process

Many crafters start with HTV if they get a cutting machine. You’ll create a design or use a design that has already been created. Your cutting machine will cut out your HTV. Then you’ll use a special tool called a weeding hook to remove the excess material so that only your design remains. The final step is to apply the HTV to a garment using a heat press or even a household iron.

HTV works best on garments and other soft textiles, however you can also use it on wood, canvas, and paper, making it somewhat versatile.

You can see the results of using the Plant Mom file on this BELLA+CANVAS dark gray heather tee. The single color pops off the dark gray shirt. A single color is cute, but wait until you see the more colorful versions below.

HTV Advantages

There are many advantages to using HTV, especially for beginners.

- It’s very easy to get started if you have a cutting machine and there are an incredible number of tutorials online for using HTV.

- Compared to the cost of the printers I’ll discuss in this post, a cutting machine and HTV are relatively inexpensive.

- It’s is great for making one-off projects, like a shirt for your kid’s school spirit day or matching shirts for a family reunion.

- With proper application and care, you can get up to 50 washes out of some HTV.

- Can be used on dark colors and most fabrics, including cotton, polyester, and blends. There are specialty versions like Stretch HTV for fabric with more stretch.

- Low time/temp brands, like Gimme5 from B-Flex, are particularly quick and easy to press.

HTV Disadvantages

Of course, no product is perfect so here are the disadvantages to using HTV.

- Cutting can be time-consuming, especially for detailed designs.

- Weeding can be time-consuming, especially for detailed designs.

- The HTV sits on top of the fabric and depending on the brand, can have a “bulky” feel.

- If not applied or cared for correctly, HTV can crack and peel up.

- You are limited to the colors and styles of HTV found on the market.

- Designs are usually single-color, though you can layer.

Best Uses for HTV

HTV is best for at-home users who want to cut and apply simple designs and text. While you can start a business using HTV, it does best for small-scale production. As your business grows, you will probably want to look at one of the following t-shirt decorating methods.

Sublimation Printing

Sublimation is a printer craft. You print out a design using a printer with sublimation ink and then you’ll use a heat press to transfer the design from the paper onto your substrate.

Sublimation can be used for way more than just garments. It’s a huge industry that just hit the at-home crafter a few years ago and many companies have taken advantage of the boom by creating fun and innovative sublimation blanks. You can find sublimation shirts, onesies, hoodies, hats, aprons, flags, mugs, tumblers, coasters, tiles, bookmarks, jewelry, pens, ornaments, and more.

There are two things you need for a substrate to work for sublimation: at least 65% polyester content or a poly coating on a hard blank, as well as a light color. The poly content allows the sublimation process to take place. And the light blank is because the ink is actually transparent. So putting it on a dark tee causes it to basically disappear.

Sublimation Process

The sublimation process is simple. Print out your design using a printer with sublimation ink (you can buy a sublimation-specific printer or you can convert a regular Epson EcoTank). Clean your substrate and tape your design face down. Then use a heat press to transfer the design to your blank.

Sublimation Advantages

Sublimation solves many of the problems that people have with HTV, while creating a few new ones. Let’s look at the advantages of sublimation first.

- Bright, vibrant full-color prints.

- A huge variety of blanks and new blanks hit the market daily.

- Compared to the other printing methods, you can get started with sublimation relatively inexpensively. You just need a sublimation printer and a heat press.

- The design becomes part of the substrate—you can’t feel it on the surface

- It’s extremely durable and washable. It will never crack or peel.

- It allows for all-over printing if you have the right equipment.

- No messy process.

Sublimation Disadvantages

I think the advantages of sublimation are some of the best, but the disadvantages might also help you decide whether or not its’s right for you.

- It’s limited to polyester and poly-coated surfaces. Not everyone wants to wear polyester garments.

- Dark-colored garments aren’t suitable for sublimation. Not everyone wants to wear white.

- It can smell. For some reason, sublimation tends to have sort of a fishy smell that some people find off-putting. It’s only while pressing, however—the final project doesn’t smell.

Best Uses for Sublimation

Sublimation is great for everyone from an at-home crafter with a converted printer to huge sublimation businesses running enormous printers and presses. If you are tired of HTV peeling and cracking and you want to make gorgeous full-color designs at a reasonable price at home, sublimation might be right for you.

Sublimation is also good for small businesses because you can easily make professional-level products at home. Being able to make a wide variety of projects can also be a great advantage for small businesses using sublimation.

DTF (Direct to Film) Printing

DTF printing is a printing method for transferring full color designs onto a variety of soft substrates, like t-shirts, tote bags, hats, and more. It involves printing your design onto a special film, applying and curing a powder adhesive, and then transferring the design onto your blank using a heat press.

DTF printing allows you to create vibrant, detailed, and durable custom apparel and other projects. The direct-to-film transfers are thin and soft and are really nice to the touch. It’s a super easy press, the peel is easy, and the feel of the transfers is so soft compared to HTV.

And because DTF printers use white ink, you can use these prints on any color garment, and you can use it on most fabric contents. This is definitely an advantage over sublimation, however DTF really only works on soft blanks. I’ve tested it on hard blanks and the only one I had good luck with was wood.

DTF Process

The process for DTF printing is much more involved than HTV or sublimation printing. You’ll use a specialized printer to print your design on film. Then you’ll carefully “powder” the wet ink by sifting a powdered adhesive over the wet ink. That adhesive then needs to be cured in a specialized oven. But after all of that, the press is super easy!

There are two ways you might go about DTF printing—having a printer in your home or ordering DTF prints online. Obviously the advantages and disadvantages will be different for these two options, so I’m going to do them both.

Ordering DTF Print Advantages

- No need to own an expensive printer.

- Easy to order from a wide variety of sites online.

- Transfers are ready to press.

- Bright, vibrant full-color prints.

- Works on a variety of fabrics, including cotton.

- Suitable for both light and dark fabrics.

- Soft feel when transferred.

- DTF prints can last 50 to 100 washes when applied properly.

Ordering DTF Print Disadvantages

- Time! You have to wait for your order to be printed and shipped to you before you can use the prints.

- Prints can be expensive.

Owning a DTF Printer Advantages

- Ability to print what you want, when you want.

- Bright, vibrant full-color prints.

- Works on a variety of soft materials, including cotton.

- Suitable for both light and dark fabrics.

- Soft feel when transferred.

- Good stretch to transfer.

- DTF prints can last 50 to 100 washes when applied properly.

- Great for small businesses.

Owning a DTF Printer Disadvantages

- There are safety concerns you’ll want to consider.

- Overall it’s a messy process that involves wet ink and powder.

- Takes up quite a bit of space for the printer, powdering station, and oven.

- The printer is expensive and requires a lot of maintenance.

- The printer can be temperamental and difficult to use.

- There’s a learning curve to get optimal results.

- Printing is slower than the other printing methods I discuss here.

- Software only works with Windows-based computers.

- Only good for soft textiles.

Best Uses for DTF

Owning a DTF printer is probably not for an at-home crafter who only wants to print occasionally. Because the printer requires nearly daily maintenance, owning a printer is better for small businesses that need a steady number of prints. But if you do have a small business, investing in a DTF printer setup might be great for creating both prints to use on all sorts of garments, as well as selling the prints themselves.

If you just want to give DTF a try without buying a printer, I would definitely order DTF prints from a DTF print seller! This is what I do.

White Toner Printing

White toner printing is similar to DTF printing in that you can print full-color images on film for use on most fabrics and all colors. The difference is in how the adhesive is applied. With white toner printing, instead of adding the adhesive as a powder, you combine your printed transfer with an adhesive sheet in a heat press.

White toner printing allows you to create vibrant, detailed, and durable custom apparel and other projects, including hard blanks and even things like mylar balloons. White toner transfers are thin and soft and are really nice to the touch. The feel of the transfers is so soft compared to HTV.

Process

Let’s look at the white toner process in more detail. Using a special toner-based printer (toner is powder vs. ink which is liquid), you’ll print your design. The printer is very fast and the ink is dry when it comes out of the printer. You’ll use your heat press to then “marry” your print with a sheet of adhesive in your heat press. The pressing itself is fairly simple as well—a press in your heat press and then a second press with a finishing sheet.

White Toner Advantages

- Bright, full-color prints.

- Works on a variety of fabrics, including cotton.

- Suitable for both light and dark fabrics.

- Can be used on more than just soft textiles, including hard blanks.

- Soft feel when transferred.

- White toner prints can last up to 50 washes when applied properly.

- Great for small businesses.

- Safer than DTF printing.

- No messy process.

- Takes up minimal space.

White Toner Disadvantages

- White toner printing tends to be the most expensive option of the bunch.

- Learning curve when it comes to the marrying process and pressing.

- Software only works with Windows-based computers.

- No black ink and it’s hard to get the blackest blacks using just cyan, magenta, and yellow.

- Transfers are less stretchy and may break down over time.

Best Uses for White Toner Printing

Because a white toner printer is expensive, the everyday at-home crafter is probably not the ideal customer. These printers are more for small businesses that want to make a wide variety of projects. That being said, if you have a big budget, then a white toner printer is much easier to have in your home than a DTF printer

What is the Best Method for T-Shirt Decorating?

As you can see, there are pros and cons with every method in this post. There really is no one-size fits all method that I think is the best. I personally have several Cricut machines for HTV, two sublimation printers, a white toner printer, and I order DTF transfers often. It really depends on what type of project I want to make, the amount of time I have, and what supplies I have on hand.

Take a look at what you want to do. If you want to make vibrant, full-color images without spending a lot of money, maybe a sublimation printer is for you. If you want to expand your thriving small business, a DTF or white toner printer might be a good option.

One nice thing is that you can order pretty much all of these types of transfers online at places like Etsy. You can order yourself an HTV transfer, a sublimation print, a DTF print, and a white toner print and do your own comparison to see what you like best.

I hope you found this comparison between t-shirt decorating methods helpful! If you have any questions about the methods I share here or other methods, please leave those down in the comments and I’ll be happy to answer them.

Comments & Reviews

Mark Zuckerberg says

I’m torn between HTV and DTF for my cotton shirts. Has anyone tried DTF on cotton shirts? I’d like to hear about Granny Game real-life experience regarding durability and color retention after multiple washes.