If you’re new to laser cutting and engraving, you may be wondering what a laser mask is. Laser masking protects your material from char marks so your projects turn out cleaner!

When I first started laser cutting, I remember reading about masking my laser materials but I wasn’t really sure what that was or what it entailed. In my last few years as a laser owner, I’ve learned a lot about masking and today I’m sharing all of my tips and tricks for masking your laser projects!

Masking is an important step that can help keep your laser projects cleaner as well as prevent “flashback” marks, as you’ll see. Masking is one of the key things you can do to make better laser projects!

If you’re new to laser crafting, you also may want to check out my post Laser Linetypes: Basic Overview of Cut, Score, and Engrave to learn more about how to get started with your laser!

Watch the Video

Want to see laser masking in action? Check out my YouTube video by hitting play below! Or keep reading for a written tutorial.

What is a Laser Mask?

A laser mask is a piece of sticky backed material that you’ll apply to your material (wood, acrylic, etc.) before you cut, score, or engrave with your laser. Think of it as a large piece of masking tape—which is basically what it is!

When your laser cuts, scores, or engraves, it creates soot and char marks as it’s working. Your laser can also leave “flashback” marks on the bottom of your material, as the laser bounces back up from the bottom plate of the laser while it cuts.

If you don’t mask your projects, you will end up with charring or flashback marks on your actual material, which is unsightly and can leave soot on your hands as you handle them.

If you do mask your projects, the marks end up on the masking, which you’ll remove after your project finishes in the laser. Then you’re left with a perfectly clean surface!

Do I Need a Laser Mask?

For most projects, I would say yes you need to mask. It’s better to mask and know you’ll have a clean project than to not mask and regret it.

If you are using a diode laser like a Glowforge Aura or xTool M1, there may be some projects where you find that masking is not necessary because the laser is just not that powerful. For example, I didn’t mask my Laser Cut Wood Ornaments and I had just a bit of charring as you can see below. You can use a magic eraser or a bit of alcohol on wood or some mild cleanser like Dawn on acrylic to remove minor charring but you may still be left with a bit.

You may also be painting your project after you’re cutting and then masking might not be as important to you.

It’s really up to you—I didn’t mind on this project I did for my kiddos, but if I was selling these ornaments, I would definitely mask them.

Masking Sizes

Masking comes in a variety of sizes. I would recommend having 12″ and 6″ masking on hand so you can mask both full sheets of laser-ready materials, as well as half-sheets for smaller projects.

Pre-Masked Materials

Some materials, like Glowforge Proofgrade materials, come pre-masked. Buying materials pre-masked often costs a bit more but there is definitely a savings in time and materials for having to mask yourself.

What is Needed for Laser Masking?

If you do need to mask your material, let’s talk about what you’re going to need.

Check out my Amazon Shopping List with all of these items in one place!

- 12″ paper masking

- 6″ paper masking

- Your material

- Craft squeegee, scraper, or brayer

- Craft knife

- Self-healing cutting mat

- 3M double-sided adhesive (see below)

Masking with 3M Double-Sided Adhesive

One other product I love that also acts as a mask is 3M double-sided adhesive. This product is amazing for assembling layered projects instead of using glue.

Instead of using paper masking on the back of your material, use the 3M double-sided adhesive. It will protect the bottom of your project from flashback marks and when you peel back the liner, your material will have a sticky back, allowing you to adhere it to your project. I used this material in my Stanley Cup Toppers and my Vintage Halloween Signs so you can see exactly how this particular product works.

Apply Laser Masking

Let’s apply our paper masking to a piece of laser material! For this example, I am using a piece of white oak from xTool and 6″ masking because I want to show you how to apply masking to a whole sheet and a half sheet.

If I am not sure whether I want the entire sheet of material masked (like perhaps I’m working on a small project, and I might want to use the rest of the material with the 3M adhesive in the future), I will mask only a portion of a sheet. We’ll start with that.

Place your material flat on your self-healing cutting mat. Then pull off a piece of mask a little longer than your material.

Adhere one end of the masking to the edge of your material.

Then use the squeegee, scraper, or brayer to work your way across the masking, trying to avoid bubbles and wrinkles.

Flip everything over and use a craft knife to cut off the excess masking, running it along the edge of your material. That way you have a straight edge for next time.

If you do have some bubbles or wrinkles, it’s not the end of the world. But if it’s bad, try re-masking. You can use your tool to help smooth out any problem areas.

If you are using 6″ masking, repeat with another row of masking below the first one. It’s okay if it overlaps a bit. If you are using 12″ masking, it should cover your material in one single piece.

Flip it over and mask the back in the same way.

Now you’re ready for engraving!

Coloring Engraving Before Removing Masking

After you cut but before you remove the masking, you may want to consider coloring in your engraving with paint pens, acrylic craft paint, or some other ink. It’s a great way to “color within the lines” on your engraving, since the masking protects the part of your material that is not engraved. You can see an example of this on my Stanley Cup Toppers. I did it with acrylic, but you can also color wood. Just note that with some woods, your paints might bleed a bit into the grain.

Removing Laser Masking

Now it’s time to remove the masking and see the final image.

You can see below what the engraving looked like on an unmasked piece of oak. The charring is pretty ugly! No one wants that on their material.

There are three ways that I like to peel back masking. It all depends on my mood and what tools I feel like using. One of these options should work best for you!

Gorilla Tape

A heavy-duty duct tape like gorilla tape works really well to remove masking. Just take a piece, adhere it to the corner of the masking, and pull up.

I have found that while this works great on masking I’ve applied mysef, sometimes it’s still not sticky enough to pull up pre-masked materials, like Glowforge Proofgrade materials. Sometimes it works, sometimes it doesn’t.

Weeding Tool

When I can’t get the edge up using gorilla tape, I often default to my weeding hook. You can pull up larger pieces with the hook and then use your hands to peel back the entire piece of masking. Just be super careful that you don’t scratch or scrape your material when you’re using it.

Plastic Razor Blade

If you have smaller pieces, especially pieces that are inside engraved parts, like the centers of my letters here, a plastic razor blade is amazing. It’s not sharp but it does the job—just run it along the top of your image and it will push up all those tiny pieces of masking that are particularly difficult to get.

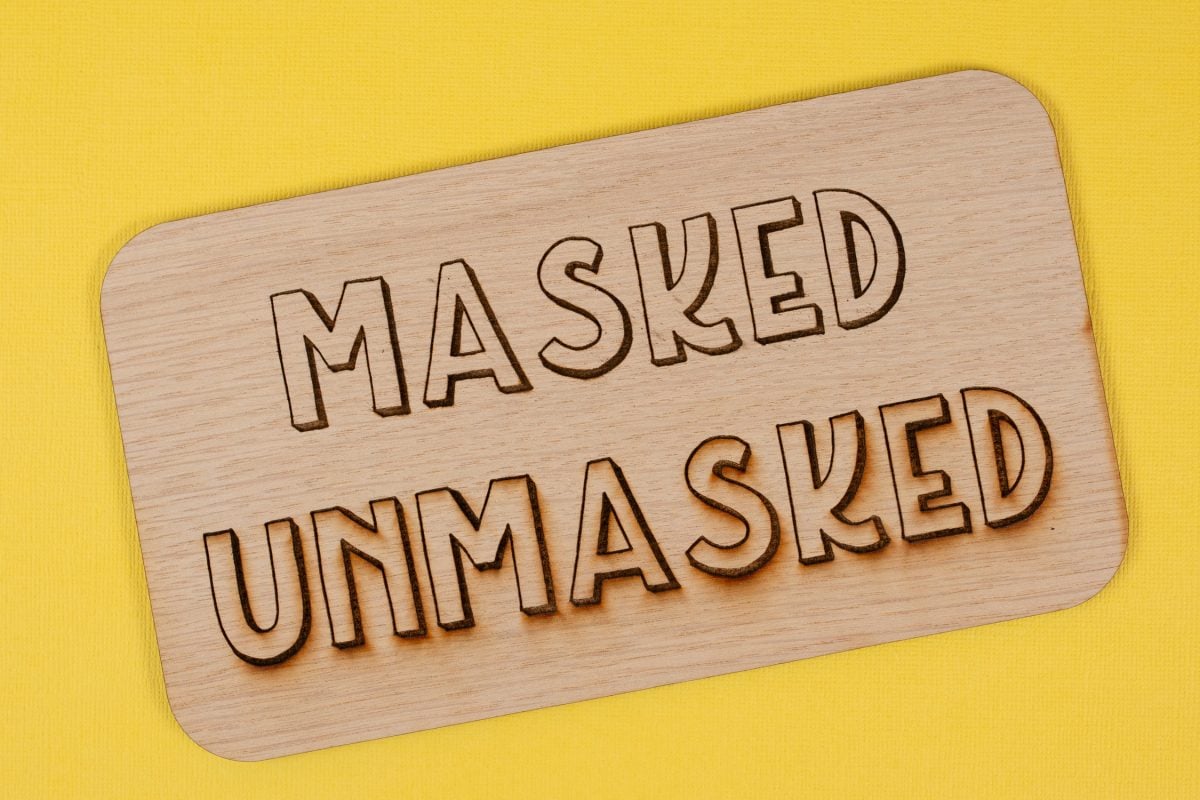

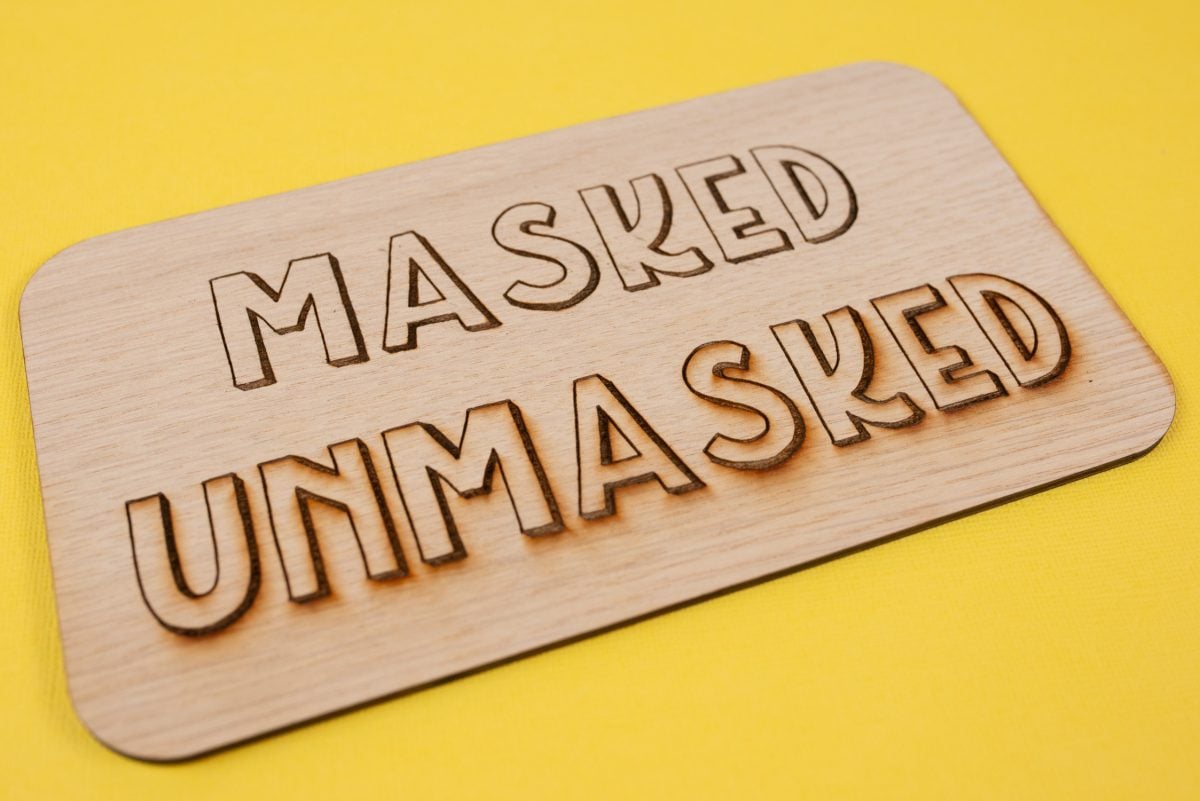

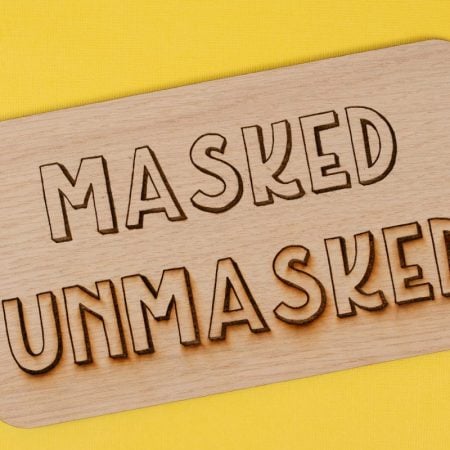

Final Result

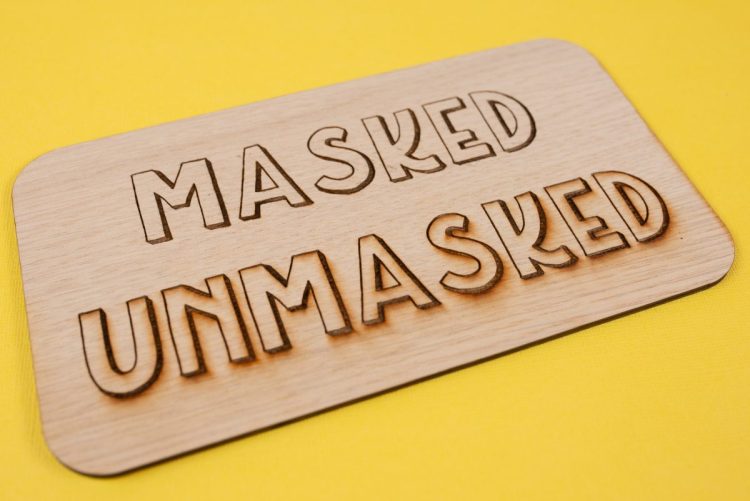

Now you can see how much better the masked portion of this test file is than the unmasked portion!

Masking can make a huge difference in your laser projects—definitely a step you probably don’t want to skip!

LASER MASKING

Supplies

- 12" paper masking

- 6" paper masking

- Your material

Instructions

- Apply Laser MaskingApply the paper masking to a piece of laser material! For this example, a piece of white oak from xTool and 6" masking is being used to show you how to apply masking to a whole sheet and a half sheet.If you are not sure whether you want the entire sheet of material masked (like perhaps you're working on a small project, and might want to use the rest of the material with the 3M adhesive in the future), so only mask a portion of a sheet. Let's start with that.Place your material flat on your self-healing cutting mat. Then pull off a piece of mask a little longer than your material.

- Adhere one end of the masking to the edge of your material.Then use the squeegee, scraper, or brayer to work your way across the masking, trying to avoid bubbles and wrinkles.

- Flip everything over and use a craft knife to cut off the excess masking, running it along the edge of your material. That way you have a straight edge for next time.

- If you do have some bubbles or wrinkles, it's not the end of the world. But if it's bad, try re-masking. You can use your tool to help smooth out any problem areas.

- If you are using 6" masking, repeat with another row of masking below the first one. It's okay if it overlaps a bit. If you are using 12" masking, it should cover your material in one single piece.Flip it over and mask the back in the same way.Now you're ready for engraving!

- Coloring Engraving Before Removing MaskingAfter you cut but before you remove the masking, you may want to consider coloring in your engraving with paint pens, acrylic craft paint, or some other ink. It's a great way to "color within the lines" on your engraving, since the masking protects the part of your material that is not engraved. You can also color wood. Just note that with some woods, your paints might bleed a bit into the grain.

- Removing Laser MaskingNow it's time to remove the masking and see the final image.You can see below what the engraving looked like on an unmasked piece of oak. The charring is pretty ugly! No one wants that on their material. There are three ways that you can use peel back masking. One of these options should work best for you!Gorilla TapeA heavy-duty duct tape like gorilla tape works really well to remove masking. Just take a piece, adhere it to the corner of the masking, and pull up.It has been found that while this works great on masking but it's still not sticky enough to pull up pre-masked materials, like Glowforge Proofgrade materials. Sometimes it works, sometimes it doesn't.

- Weeding ToolIf you can't get the edge up using gorilla tape, try using your weeding hook. You can pull up larger pieces with the hook and then use your hands to peel back the entire piece of masking. Just be super careful that you don't scratch or scrape your material when you're using it.

- Plastic Razor BladeIf you have smaller pieces, especially pieces that are inside engraved parts, like the centers of the letters are here, a plastic razor blade is amazing. It's not sharp but it does the job—just run it along the top of your image and it will push up all those tiny pieces of masking that are particularly difficult to get.

- Final ResultNow you can see how much better the masked portion of this test file is than the unmasked portion!Masking can make a huge difference in your laser projects—definitely a step you probably don't want to skip!

Comments & Reviews

Peter de Wit says

Unfortunately, I don’t think I can use masking. All my work is print then cut, on a Glowforge, My designs are printed on a4 Epson self-adhesive paper, which I stick onto plywod, then I cut the .svg print file on Glowforge. I think masking tape would damage the printed desigm. ( You can see my work on my Facebook page, Peterdewittoymaker, If you want to see what I am taling about).

Best Regards