Wondering what the air assist can do for your laser? Here’s how laser air assist helps you craft cleaner, better, and safer laser projects!

If you’re new to laser crafting, you’re probably wondering what air assist is. This is a feature that comes built-in on some laser machines, and as an add-on to other machines. But…is it necessary?

What is Laser Air Assist?

Air assist is a feature in laser cutting and engraving machines that directs a stream of compressed air onto the material’s surface while it’s cutting, scoring, and engraving. This stream of compressed air has many benefits, which we’ll talk about in this post.

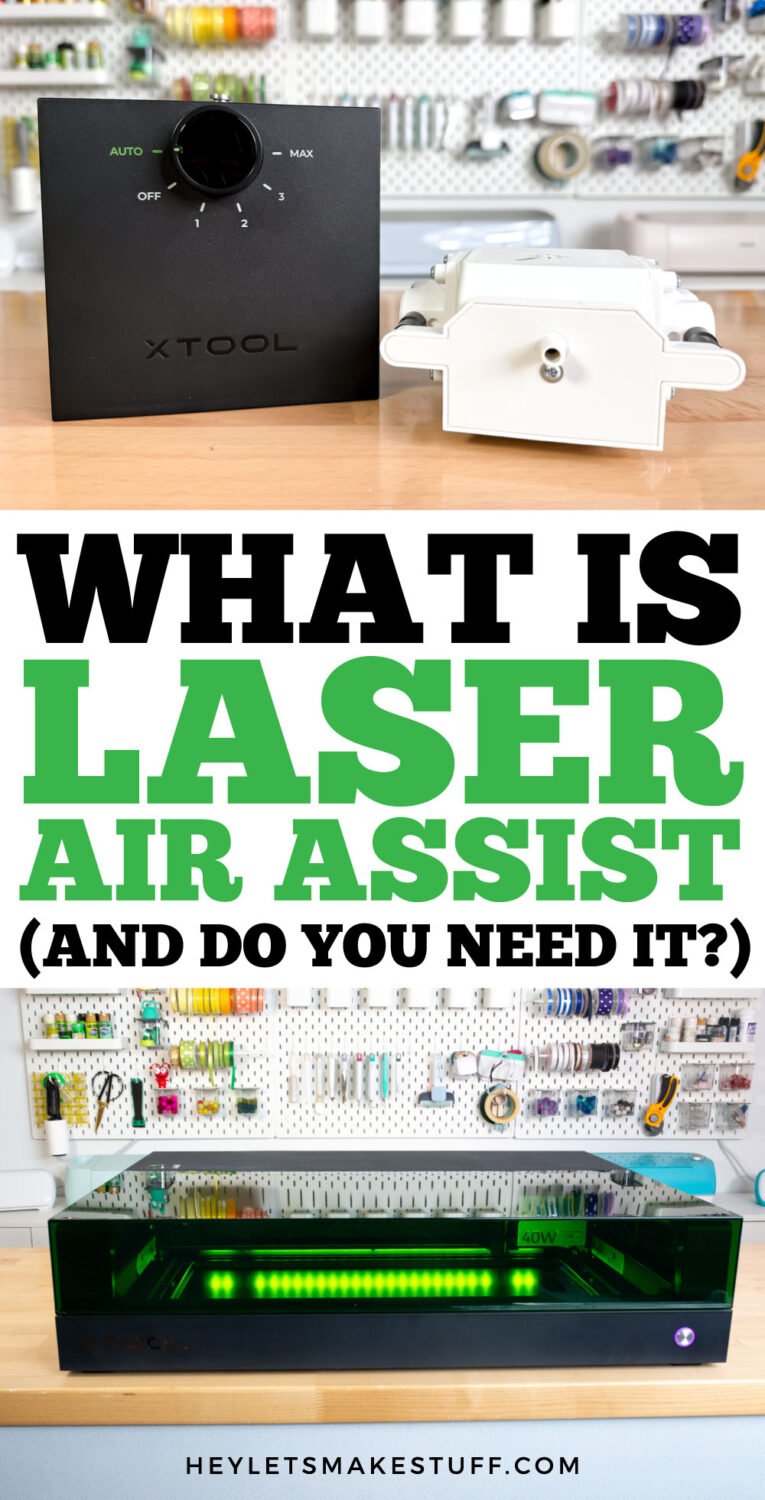

Here are the lasers I have and whether or not they come with air assist:

- xTool P2S – built in, can manually adjust down to 30% but cannot turn off

- xTool S1 – separate adjustable accessory, purchased separately

- xTool M1 – separate adjustable accessory, purchased separately

- xTool M1 Ultra – separate non-adjustable accessory, comes with purchase

- Glowforge Pro – built in, automatically adjusts

- Glowforge Aura – built in, automatically adjusts

- Glowforge Spark – built in, automatically adjusts

- WeCreat Vista – separate non-adjustable accessory, comes with purchase

- WeCreat Vision – separate non-adjustable accessory, comes with purchase

Now you can see why air assist can be confusing to new users! Some machines have it built in, and some it’s a separate accessory. Some you can adjust and some you can’t. It’s definitely not straightforward, so don’t feel bad if you’re confused!

Let’s talk about the benefits of using air assist with your laser.

Benefit #1: Enhanced Performance

The continuous airflow helps dissipate heat more efficiently, allowing for cleaner cuts. Without air assist, the smoke and vaporized material produced during cutting and engraving can settle back onto the surface, leaving behind charring and discoloration. Air assist helps blow away this debris immediately, resulting in cleaner, crisper edges.

Benefit #2: Improved Edge Quality

Air assist minimizes the formation of oxide layers, resulting in cleaner edges without discoloration or residue. In some cases, this allows you to do fewer passes or less power for your projects, saving you both time and wear on your laser.

Benefit #3: Lens Protection

Your laser’s lens is a critical component that directs the laser beam onto your material. Keeping it clean is essential to keep your laser working well. When cutting or engraving, smoke, dust, and tiny particles rise up toward the laser head. If these contaminants settle on the lens, they can block or scatter the laser beam, reducing efficiency and potentially damaging the lens over time.

Air assist helps create a protective barrier by directing airflow downward, keeping smoke and debris away from the lens. This not only extends the lifespan of your lens but also means you don’t have to clean your lens as often.

Benefit #4: Increased Safety

Fire hazards can be a concern when using a laser machine, especially with flammable materials. Without proper airflow, small flare-ups can ignite, leading to fires inside your laser.

Air assist significantly reduces this risk by dispersing heat and pushing flammable particles away from the laser beam. This is particularly important for long or high-powered cuts where heat buildup is more likely. By reducing the chance of flare-ups, air assist makes laser cutting a safer process overall.

When NOT to Use Air Assist

While air assist will generally make your projects better, there may be a handful of projects where you want to turn it off. For example, in forums I’ve read that some people don’t like to have air assist on when engraving on glass, because the airflow can interfere with how the laser is interacting with the glass. Just be aware that for some projects, you may want to do a test with and without the air assist (if that’s possible with your particular laser).

Test, Test, Test

Speaking of testing…as with anything having to do with a laser, using air assist may require testing!

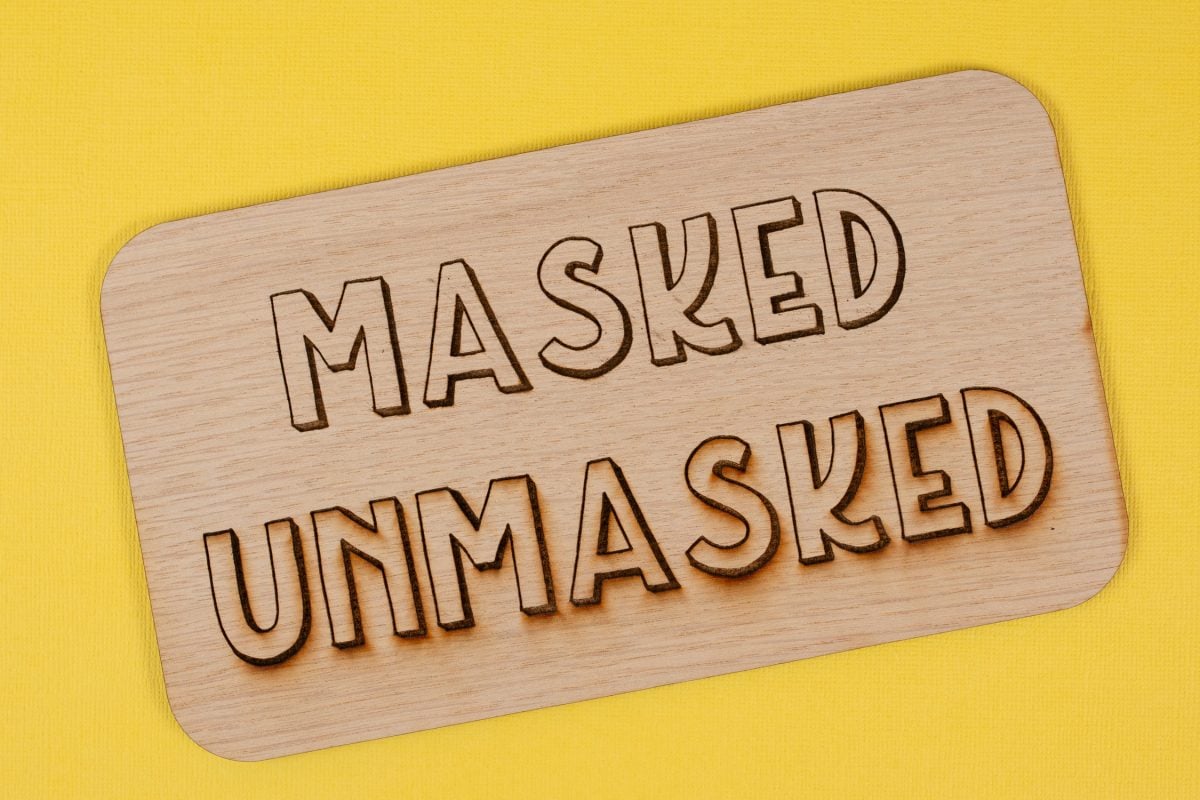

There are some materials and cut settings where you may not need the air assist (like I mentioned above). And there may be some where you lower or increase the amount of air flow based on your project (if that’s a possibility for your machine). If you are still seeing charring while using air assist, make sure there are no kinks in the air hose and you may want to mask your materials.

Do You Need Air Assist?

Technically, no, but I do think it’s one of the best accessories you can get with your laser. Getting cleaner cuts with a safer laser machine is definitely worth the money!

Comments & Reviews

bruclee says

Great explanation of why air assist matters. I’m thinking about upgrading my hole io laser. What’s the biggest improvement you’ve noticed after adding air assist to your workflow?